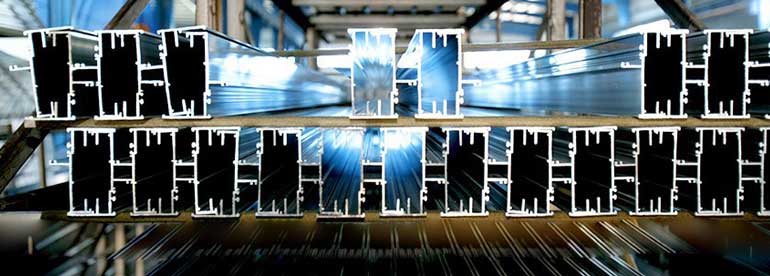

Extrusion is defined as the process of shaping material, such as aluminium, by forcing it to flow through a shaped opening in a die. Extruded material emerges as an elongated piece with the same profile as the die opening.

In aluminium extrusion process, a billet is heated to an appropriate temperature and then pushed under high pressure by a hydraulic press through a shaped opening in a special steel die. The profile crosssection of which corresponds the opening of the die is then quenched, stretched, cut to required length and finally aged to achieve a desired hardness.

Extrusion profiles are available in various alloys and tempers so as to provide a wide range of mechanical and physical properties.

G Das Industries operate press of 1450 US tons with 6 inches billets. The rated capacity is 3,500 tons per year. Our extrusion presses are positioned to efficiently uphold the manufacturing process; allowing us to provide consistent lead-times in the industry and on-time delivery performance.Press is operated to strict standards ensuring superior extrusion with excellent surface quality. High tolerance aluminium extrusions are provided using commercial alloys, 6061 and 6063, subject to temper requirements and products specification.G Das Industries also provides both custom and standard shapes based on customer’s requirements.

Block 295(Model Farm)

Plot: 321, 498 – 504. 506, Kyaggwe, Mbiko, Njeru.

P.O.Box – 1069, Jinja, Uganda.

Kampala Outlet: Plot: 155 – 165, Sixth Street,

Next to CHINT Electronics,

Kampala, Uganda.